Welcome to X-Meritan to buy the latest promotions, affordable prices, and excellent qualityGeneral TE Coolers with Serial or Paralles for Special App . We look forward to cooperating with you.

The choice depends on the specific application. Universal TE coolers offer high efficiency and compact design, excelling in specialized applications. As a dedicated supplier, X-Meritan offers universalGeneral TE Coolers with Serial or Paralles for Special App . Please contact us for details regarding your company's needs.

In a series configuration, multiple TE coolers are connected in series to form a continuous cooling circuit.

1. Because the fluid passes through each cooler in sequence, flow distribution is even, eliminating the problem of biased flow caused by uneven flow distribution.

2. In a series system, the fluid channels are relatively concentrated, resulting in higher flow velocities, enhancing convective heat transfer and improving the overall heat transfer coefficient.

3. The need to pass through multiple coolers in sequence creates a long flow path and high resistance, resulting in a high overall system pressure drop.

4. Using a series configuration in high-flow systems may be limited by excessive pressure drop and high energy consumption.

1. The parallel configuration is ideal for applications with high flow rates, such as industrial cooling systems and heat dissipation for large machinery.

2. Each cooler handles only a portion of the flow, shortening the flow path and reducing the overall system pressure drop. This helps reduce pumping energy consumption, reduces the burden on the power system, and improves operating efficiency.

3. The number of coolers can be adjusted based on actual needs, facilitating system expansion and maintenance. Users can flexibly add or reduce the number of coolers based on load changes, achieving on-demand configuration.

|

Feature |

Series Configuration |

Parallel Configuration |

|

Flow Control |

Strong flow control, uniform flow distribution |

Weak, requires optimized flow control |

|

Heat Transfer Efficiency |

High heat transfer efficiency, high flow rate, high heat transfer coefficient |

Depends on flow distribution |

|

Pressure Drop |

High pressure drop, high energy consumption |

Low pressure drop, low energy consumption |

|

Flow Rate |

Small flow rate, suitable for high heat flux and low flow applications |

Large flow rate, suitable for high flow systems |

|

Structural Flexibility |

Poor structural flexibility, limited scalability |

High, easy to expand and maintain |

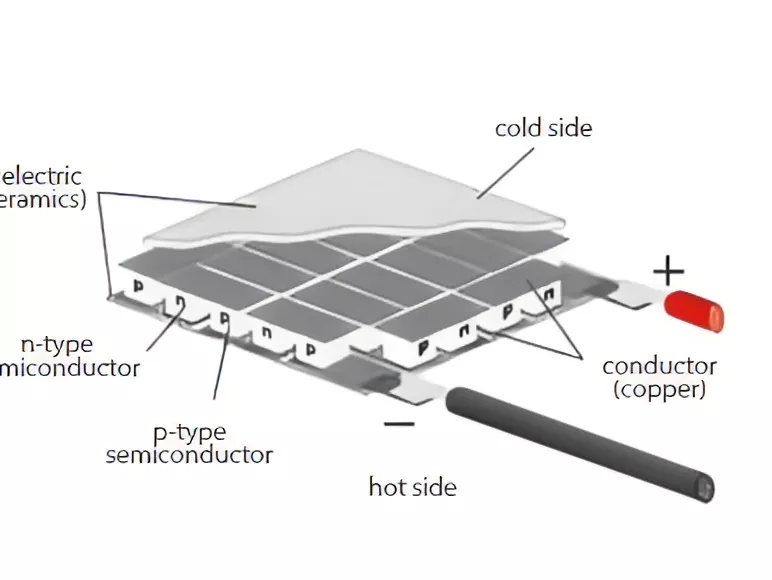

TE Technology has technical expertise in all relevant disciplines applicable to thermoelectrics. Over forty years of thermoelectric experience go into every product. In addition, we have specialized test equipment unique to the thermoelectric industry that enables quick (inexpensive) and accurate test results on 100% of our products (click here for more information). We provide reliable, durable, cost-effective systems, and we provide them on-time. Our large inventory, state of art machining and vast global resources provide added versatility from prototype to production manufacturing.